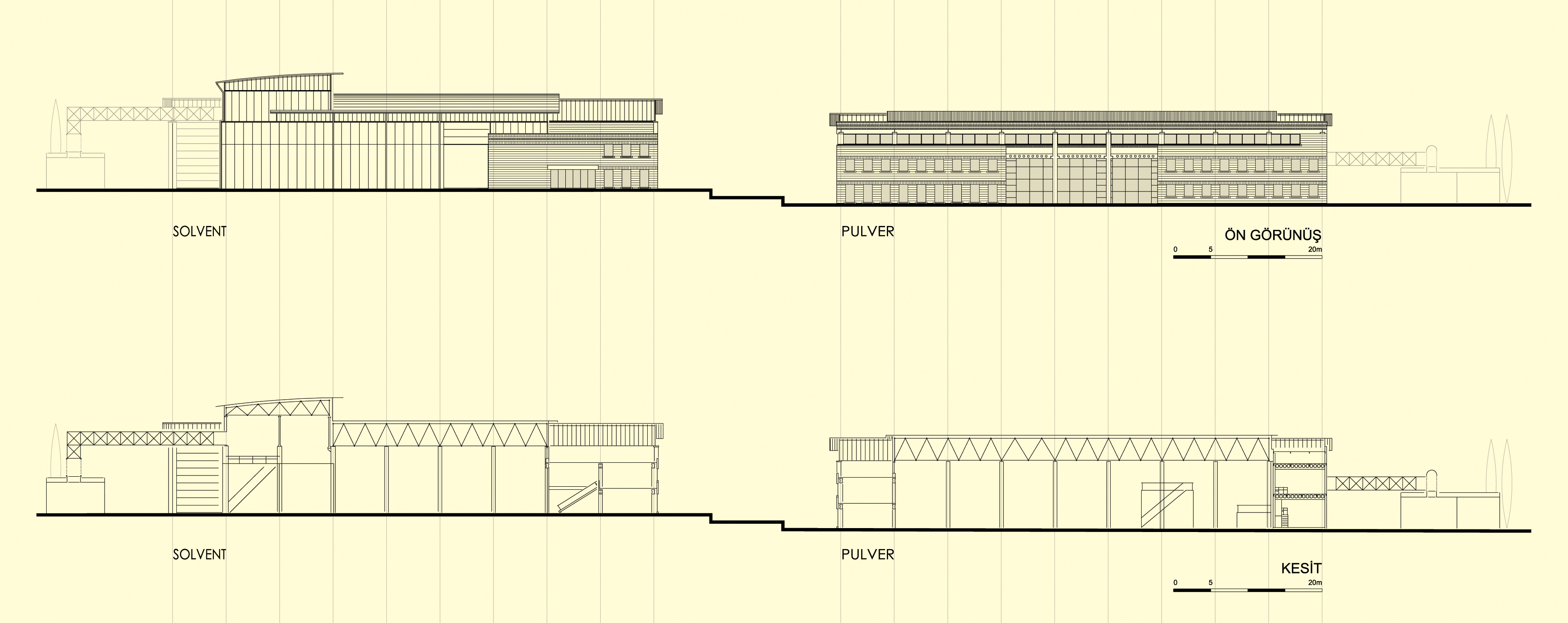

PULVER-ELASTRON FACTORIES

Gebze/Kocaeli︎ 1998 ︎ Construction Area: 17.000 m2 ︎ Site: 32.000 m2 ︎ Endüstri ︎ Emre Özberk, Mert Eyiler, Nevzat Sayın, Tülay Atabey

![]()

Gebze/Kocaeli︎ 1998 ︎ Construction Area: 17.000 m2 ︎ Site: 32.000 m2 ︎ Endüstri ︎ Emre Özberk, Mert Eyiler, Nevzat Sayın, Tülay Atabey

Although they belong to the same employer, they are two completely independent factory structures. Pulver produces electrostatic powder coating. Elastron produces thermo rubber. Both are truly industrial buildings. Since the production machines are large-sized units that are very difficult to change over time, the most difficult part of this issue was the process of determining the production flow and deciding on the machine layout. The employer's command of the subject was a very important factor in the success of this work phase. We were able to reach a scheme that worked well in the intersection of his conclusions and the conclusions we found by observing.

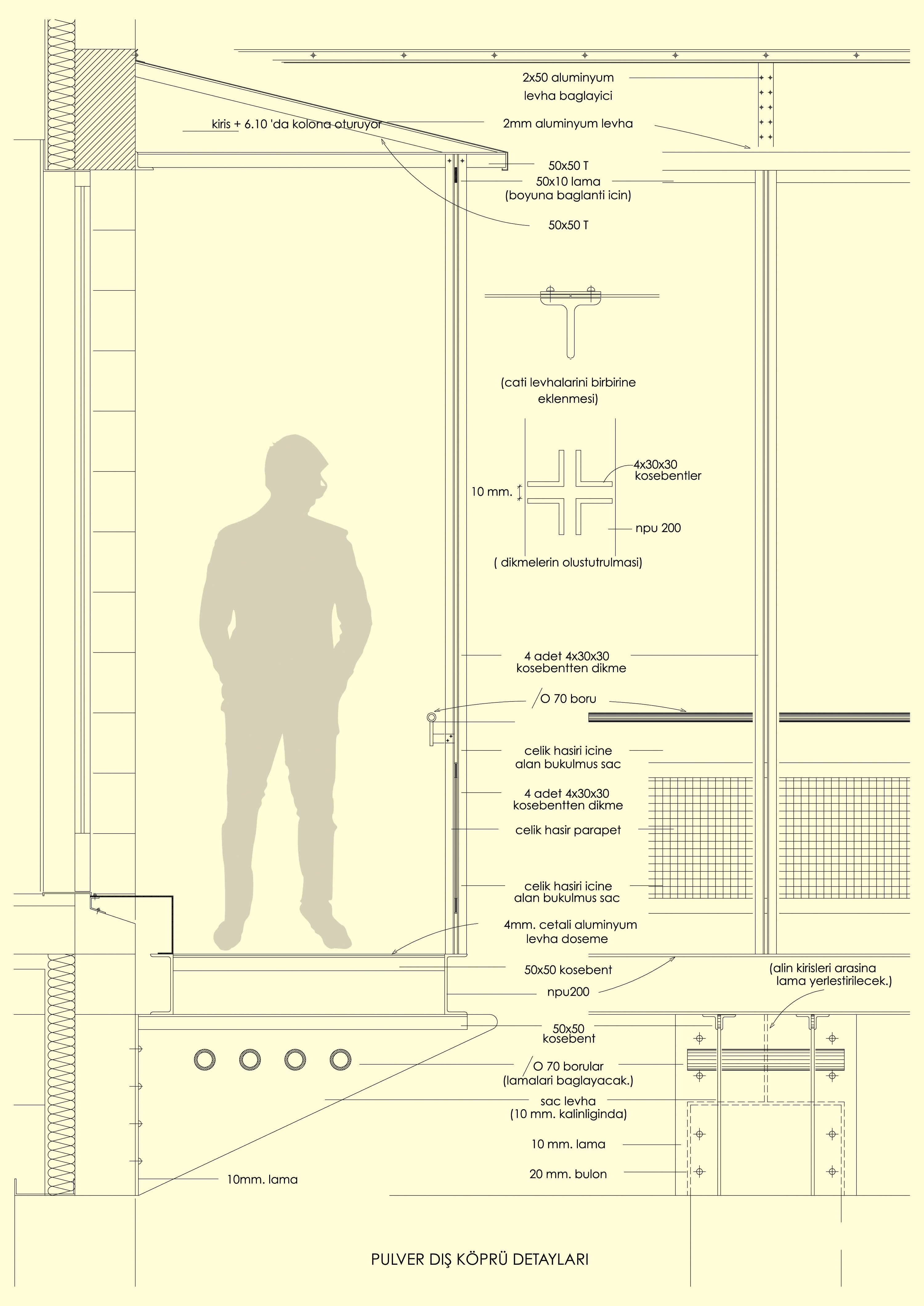

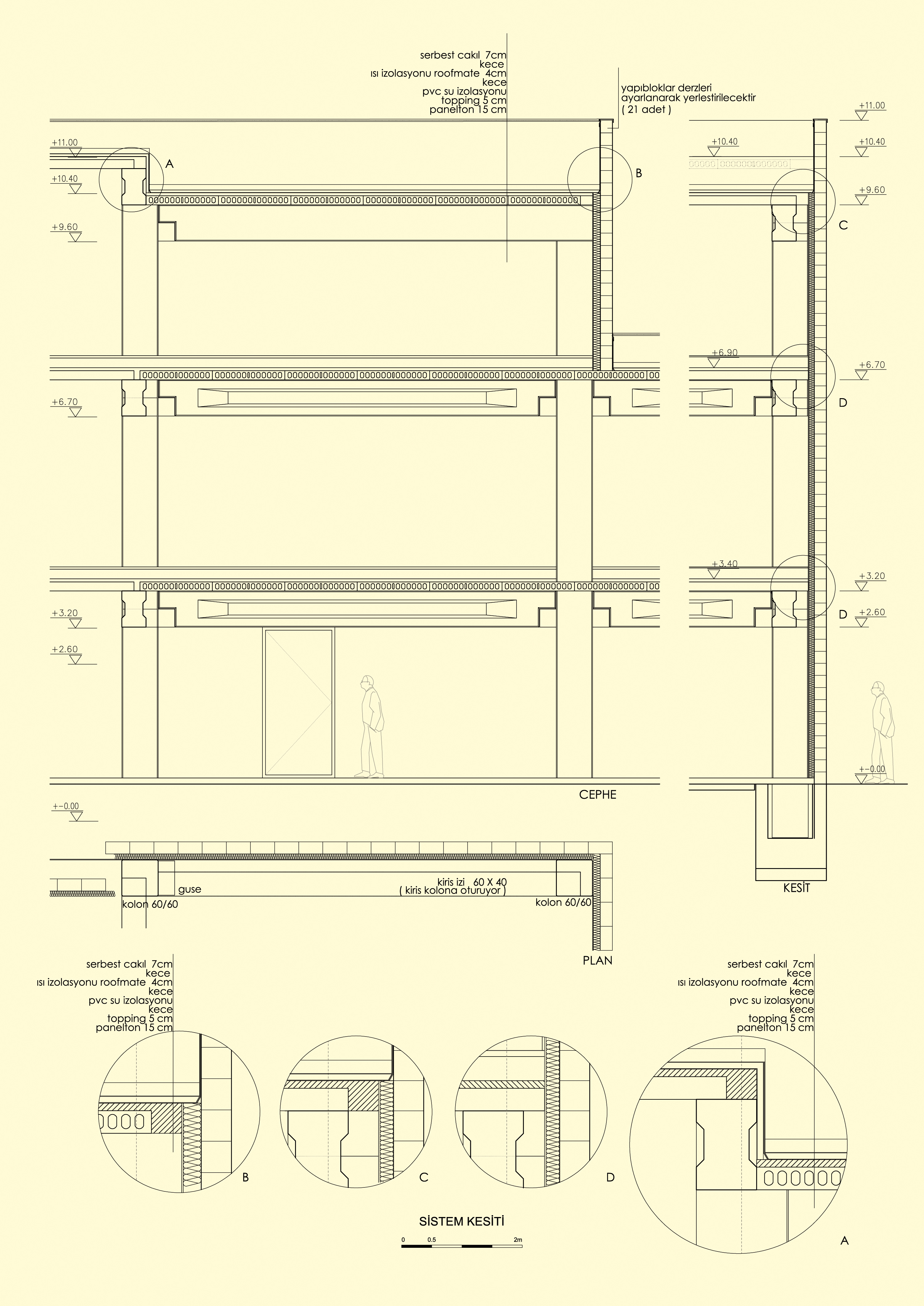

We recommended prefabrication as a construction method and we did so. In both factories, the main body was constructed with reinforced concrete prefabricated elements. The roof, secondary units and ‘internal structures’, which could not be determined at the beginning with the fabrications above the +09.00 level, were made of steel. In the management units, the materials and details of the production units were partially transformed and used. The energy and installation units were separated from the building and built adjacent to the garden wall and connected to the main structure by galleries.The interior of this building, which looks quite calm, is incredibly complex. The general habit is that there is no need for an architect in industrial buildings. However, when we look closely at this building, we think the opposite, that the architect is most necessary in these buildings.